Effective load securing in the vehicle fleet is of great importance to ensure both road safety and the protection of loads and vehicles. A carefully planned and implemented load securing process minimizes the risk of accidents, damage to the load and reduces negative effects on the transport itself. Important aspects and methods for securing loads in the vehicle fleet and what to look out for are outlined below.

Contents

Load securing in the fleet: What do fleet managers need to consider?

Among other things, fleet managers must ensure that employees are provided with roadworthy vehicles. In Germany, the employer is liable for the vehicles in the fleet.

Here are the most important aspects that should not be ignored:

- Find out about the applicable legal provisions and regulations on load securing. This includes the German Road Traffic Regulations (StVO), regulations of the employers’ liability insurance association (BGV ) and, if applicable, specific regulations for certain types of loads.

- Make sure that your drivers receive regular training courses on load securing so that their knowledge is always up to date.

- Check the condition of the load securing devices and equipment in your vehicles at regular intervals. These should function properly and comply with current standards.

- Establish clear guidelines and procedures for load securing in your fleet. Ensure that your employees comply with these guidelines and review them regularly.

- Document the load securing measures and inspections carried out and carefully store records of training, inspections and any incidents relating to load securing.

What legal regulations must be observed when securing a load?

Various statutory and legal regulations must be observed when securing loads. In Germany, the Road Traffic Regulations (StVO) and the Employer’s Liability Insurance Association Regulations (BGV) are of crucial importance. The StVO stipulates that the load must be secured in such a way that it cannot slip, fall over or fall down during transportation and does not endanger the stability of the vehicle.

According to § Section 22 para. 1 of the StVO (Road Traffic Regulations) applies:

“The load, including load securing devices and load equipment, must be stowed and secured in such a way that they cannot slip, fall over, roll back and forth, fall down or generate avoidable noise, even in the event of emergency braking or sudden evasive action”.

The BGV supplements these regulations and places further requirements on load securing, particularly in the commercial sector. In addition, special regulations apply to certain types of loads such as dangerous goods or unusually shaped loads. Failure to comply with these regulations can result in fines and points being entered in the central traffic register. These fines can range from 20 euros to several hundred euros.

In the case of serious violations that endanger or harm other road users, the fines may be higher and there is a risk of points in Flensburg. Compliance with legal regulations is therefore essential to ensure safe and legally compliant load securing.

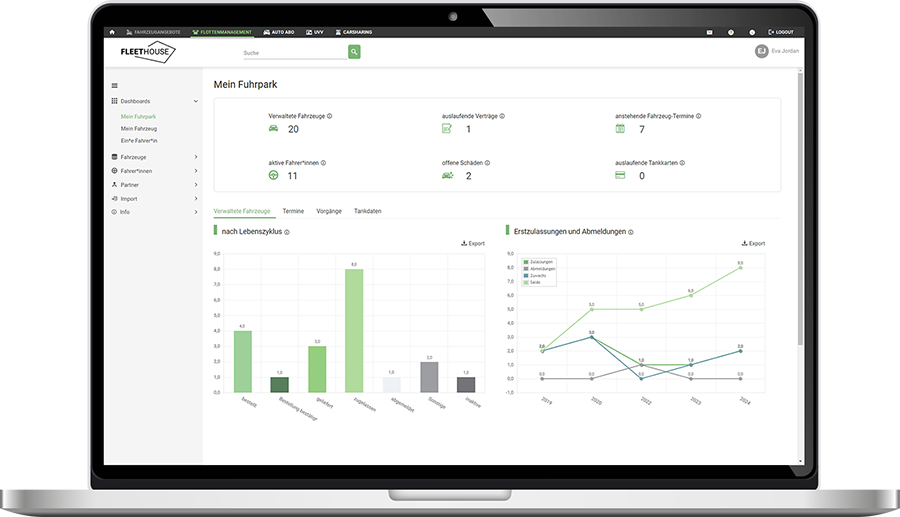

The software for your fleet

What should be taken into account when securing loads?

Proper load securing is crucial for trucks, vans, cars and trailers in order to ensure safety on the road. The most important aspects to be observed when securing loads are summarized below:

- Selection of suitable load securing equipment such as lashing straps, tension rods or anti-slip mats

- Checking the load securing before the start of the journey and regular checks during transportation

- Consideration of special requirements for certain loads such as hazardous goods, heavy loads or unusually shaped loads

- Even distribution of the load on the loading area to avoid one-sided loading

- Sufficient number and quality of lashing points (if available) to secure the load

- Checking the load-bearing capacity of the lashing points and loading area

- Observe the permissible payload limits of the vehicle to avoid overloading

- Secure fastening of the load in the trunk or on the loading area

- Avoidance of loose objects in the vehicle interior

- Careful placement of heavy or bulky objects so as not to obstruct the driver’s view

Lashing points are fastening options in vehicles or trailers, such as metal eyelets, hooks or rails, to securely attach the load securing equipment. They serve as anchor points to protect the load from slipping or falling during transportation.

Load securing for a trailer

- Secure connection between trailer and towing vehicle using suitable coupling systems

- Checking the trailer axle and tire pressure to ensure stable vehicle handling

- Securely fasten the load to the trailer to prevent it from slipping or falling off

- Observe the special regulations for trailers, such as the use of support legs when parking

Who is responsible in the fleet in the event of improper load securing?

In the event of damage to the vehicle due to improper loading, both the shipper and the vehicle driver generally bear a certain degree of responsibility. The fleet management can also be held liable within the scope of the so-called owner liability can also be held liable. It has a duty to ensure the safety of the load and to comply with the statutory regulations on load securing. If fleet managers neglect their duties to properly train drivers, check load securing equipment and comply with regulations, or fail to ensure that loads are properly secured, they can be held liable for damage.

According to German legislation, the shipper is responsible for properly securing the load and ensuring that it does not slip, fall over or fall down during transportation. The vehicle driver, in turn, is obliged to check the load securing before setting off and to make any necessary improvements.

(...) the consignor must load, stow and secure (load) and unload the goods safely for transportation. The carrier must ensure safe loading.

Handelsgesetzbuch § 412 Absatz (1) Verladen und Entladen

Training courses on correct load securing in the vehicle fleet

Training on load securing in the fleet is crucial to ensure that employees have the necessary knowledge and skills to secure loads correctly and minimize potential risks. These training courses provide participants with an understanding of the legal requirements and regulations relating to load securing and the importance of proper securing.

During the training courses, employees learn about various load securing techniques, including the correct use of load securing equipment such as lashing straps, tension rods and anti-slip mats. You will receive instructions on how to calculate the required securing forces and how to distribute the load on the vehicle.

The training also includes practical exercises to learn how to use load securing equipment correctly. Participants are informed about potential dangers and risks associated with improper load securing, such as load slippage, overloading or lack of vehicle stability.

The most important facts about load securing in the fleet

Training and regular further training of drivers is necessary to ensure their knowledge and skills in load securing.

It is important to have clearly defined guidelines for load securing, which vehicle drivers and shippers must observe.

Regular inspections and maintenance of load securing equipment and vehicles are necessary to guarantee safety.

Further Fleet Knowledge

If you liked this article and would like to know more about this topic, we recommend these articles.

Owner liability in the fleet: what fleet managers should bear in mind