Regular fleet maintenance is the responsibility of the fleet manager. But what exactly does maintenance mean in the context of fleet vehicles and why is it so important? In this article, you will learn why proper maintenance is essential for every fleet and which dates you should always keep an eye on in your maintenance planner. In times of digitalization, fleet management software can be an important support in the organization of data, documentation and maintenance in the fleet. Software increases the efficiency and safety of your fleet and saves valuable time and money.

Contents

What does maintenance mean in the fleet?

Maintenance is an important issue in the fleet and should ensure that all vehicles in the fleet are ready for use at all times. Maintenance work can apply to all parts of the vehicle, including the engine, tires, brakes, fuel system and many other components. Typical fleet maintenance work includes, for example, regular oil changes, brake checks, tire changes and inspections. All measures help to ensure that the vehicles function reliably and that the risk of breakdowns or accidents is minimized as far as possible.

Observe maintenance intervals

The maintenance intervals in the vehicle fleet are of great importance, as they specify the time at which maintenance must be carried out. These maintenance intervals are often specified by the manufacturer and are noted in the vehicle’s service booklet. The maintenance intervals vary depending on the vehicle type and conditions of use. Some vehicles may require more frequent maintenance than others, especially if they are used in extreme conditions such as heavy use or poor road conditions. Fleet managers must keep an eye on maintenance intervals and organize maintenance in good time to avoid expensive consequential damage or breakdowns. Documentation of the work carried out on the vehicle is also essential.

Why is fleet maintenance important?

Regular fleet maintenance has several advantages. On the one hand, it ensures that vehicles are always ready for use and minimizes the risk of unforeseen breakdowns. This is particularly important for companies that depend on a reliable fleet to keep their operations running.

Secondly, regular maintenance work helps to extend the service life of the vehicles and reduce repair costs. Early inspection and detection of wear or defects can prevent expensive consequential damage and repairs. You also ensure that all vehicles always comply with legal requirements and that your employees are safe on the road by adhering to maintenance schedules.

Important dates for fleet maintenance that must be included in every maintenance planner

You should keep the following dates in mind when carrying out maintenance on your fleet:

- Oil change: Depending on the manufacturer and vehicle type, the oil must be changed at regular intervals. This protects the engine and maintains its performance. As a rule, an oil change is recommended every 15,000 to 30,000 kilometers – or at least once a year.

- Brake test: The brakes are a safety-relevant component on the vehicle. It is therefore important to carry out a regular brake inspection to check the condition of the brake pads, brake discs and brake lines and to repair or replace them if necessary.

- Changing tires: Tires also play a decisive role in road safety. The tires must be changed depending on the weather conditions and the time of year. In Germany, for example, winter tires are mandatory by law.

- Inspection: During an inspection, all important components and functions of the vehicle are checked for functionality and safety. Minor tasks such as topping up oil or changing filters are usually also carried out during the inspection. An important date that no maintenance planner should be without!

- Exhaust emissions test: The exhaust emissions test (AU) is required by law and is used to check the vehicle’s emission values and ensure that it complies with the applicable environmental standards. The AU must be carried out at regular intervals.

- Main inspection: The main inspection (HU) is also required by law and checks the roadworthiness of the vehicle. The brakes, lights and steering, for example, are checked. The general inspection must be carried out every 1-2 years, depending on the vehicle type and age.

- Air conditioning maintenance: The vehicle’s air conditioning system must also be serviced regularly in order to maintain its functionality and performance. The replacement of refrigerant and filters is particularly important here.

- Battery replacement: The battery is a wearing part and must be replaced depending on its age and period of use to ensure that the vehicle starts reliably.

- Timing belt replacement: In many vehicles, the timing belt must be replaced at regular intervals to prevent damage to the engine.

- Electronics updates: With newer vehicles in particular, it is important to carry out regular updates to the electronic control systems to ensure that the vehicle is always up to date and functions optimally.

Software with an integrated maintenance planner can help you keep track of things and remind you of upcoming maintenance work in good time.

Fleet Management

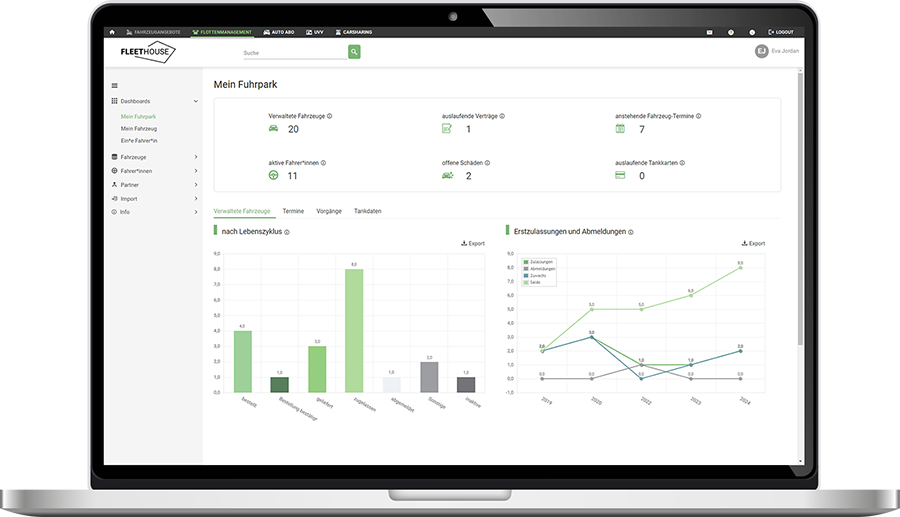

Organize all tasks relating to your vehicles with Fleethouse.

How software helps with fleet maintenance

With software, you automatically have an overview of all upcoming maintenance dates and important information about your fleet. Modern fleet management software solutions offer functions such as automatic reminders for upcoming maintenance work and automatic monitoring of maintenance intervals. This guarantees that no maintenance dates are overlooked.

In addition, fleet management can use software to document and manage the entire maintenance history of all vehicles. This means you always have all the information you need and an overview of which maintenance work has been carried out on which vehicle. You can access it quickly if required. This can be particularly advantageous when selling or exchanging vehicles, as potential buyers or lessors often want a detailed maintenance history.

Software can also help to monitor and analyze the costs of maintenance work and repairs. Using the information from the software, fleet management can optimize fleet maintenance expenditure in a targeted manner and identify potential savings.

Arrange an online consultation appointment

Arrange your personal consultation appointment now. You can easily select a suitable appointment using our booking tool.

Anne Fuchs

Ciara Lazeta

The most important facts about fleet maintenance at a glance

Regular maintenance work is essential to ensure a reliable and safe fleet.

Various maintenance intervals must be taken into account by fleet management in order to avoid expensive consequential damage, any unnecessary repairs and breakdowns in the fleet.

Modern software functions as a digital maintenance planner and can help you keep track of all dates and deadlines, document the maintenance history of your vehicles and monitor and optimize the costs of maintenance work.

Further Fleet Knowledge

If you liked this article and would like to know more about this topic, we recommend these articles.

Claims management: The 1×1 for fleet managers